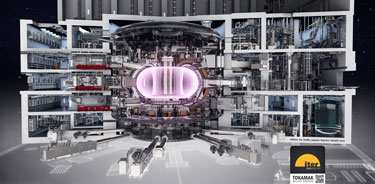

Cadarache/Alzenau, 12th June 2018. ITER is a tokamak under construction in Cadarache, France. Its goal is to demonstrate the feasibility of producing energy by fusion reaction of Deuterium and Tritium. The machine should generate first plasma in December 2025. Before construction is even finished, the deactivation and dismantling was analyzed already.

For the ITER Deactivation study a consortium of the companies AMEC Foster Wheeler (now known as WOOD PLC and supported by AJR consulting) and NUKEM Technologies Engineering Services GmbH (NTES) was selected. Within the consortium French, UK, and German knowledge on nuclear issues was present.

In close cooperation with ITER Organization about 100 documents needed to be mined for relevant information to get to a good understanding of the equipment which will be deactivated and dismantled after the end of plasma operations of ITER. The documents had sometimes several hundred pages (e.g. the Safety Report of ITER) or otherwise huge dimensions (e.g. the “Bill of materials” with information on materials used for ITER construction contains several hundred thousand cells …). The 3D-Models of all facilities of ITER which will be under French nuclear legislation were essential for the analysis to get a good understanding not only on the equipment’s location and dimensions, but also on accessibility. Additional information on safety parameters of the rooms (radiation zones, ventilation zones etc.) needed to be brought together to better understand possible restrictions.

Throughout the project the expertise of France, UK and Germany present in the consortium was used to estimate the working procedures and time requirements for all deactivation operations required. In some cases knowledge based assumptions where developed.

For some parts of ITER the analysis was performed depending on the systems, while for others the analysis was performed on a Level by Level and Room by Room base. Due to the changes partly resulting from the first analysis results the basis of the analysis needed to be changed within the process. When needed, assumptions on the parameters of the equipment required for the deactivation analysis could be made based on the experience of the consortium and approved by ITER leading to a common basis for the analysis.

The project’s success was based on the wide knowledge base provided by the participating companies. The frequent meetings within the consortium and with ITER staff were very helpful to get a clear understanding of the processes within all facilities. The cooperation was on a very good level of understanding of each other even with some surprises concerning different regulations on how to process or treat radiological issues. The sequencing of all necessary steps to deactivate the whole plant took into account not only tritiated waste treatment issues but always put safety first e.g. by establishing specific methods of operations. For example before any room is entered by personnel the first action is to decontaminate the rooms, if necessary using robots. The study does not take into account future possible dismantling methods but is based on existing methods.

It was proven that the safe deactivation of ITER is possible. After the presentation of the results to ITER at the final meeting mid of March, ITER expressed its full satisfaction to the consortium team.

NUKEM Technologies in Alzenau, Germany, is world-wide active in the areas of management of radioactive waste and spent fuel, decommissioning of nuclear facilities, engineering and consulting. For more than 60 years NUKEM Technologies provides high quality products, technologies and services, where Innovation, Solutions and Excellence are closely linked.

Contact:

Bea Heinze

NUKEM Technologies GmbH

Industriestrasse 13, 63755 Alzenau

Tel: +49 6023 91-1549,

E-mail:

www.nukemtechnologies.com