-

05 February 2025

Safe Decommissioning with Cutting-Edge Technology: NUKEM and UNS Complete Fleet Dismantling in Sweden with Final Reactor Pressure Vessel Successfully Dismantled at Oskarshamn

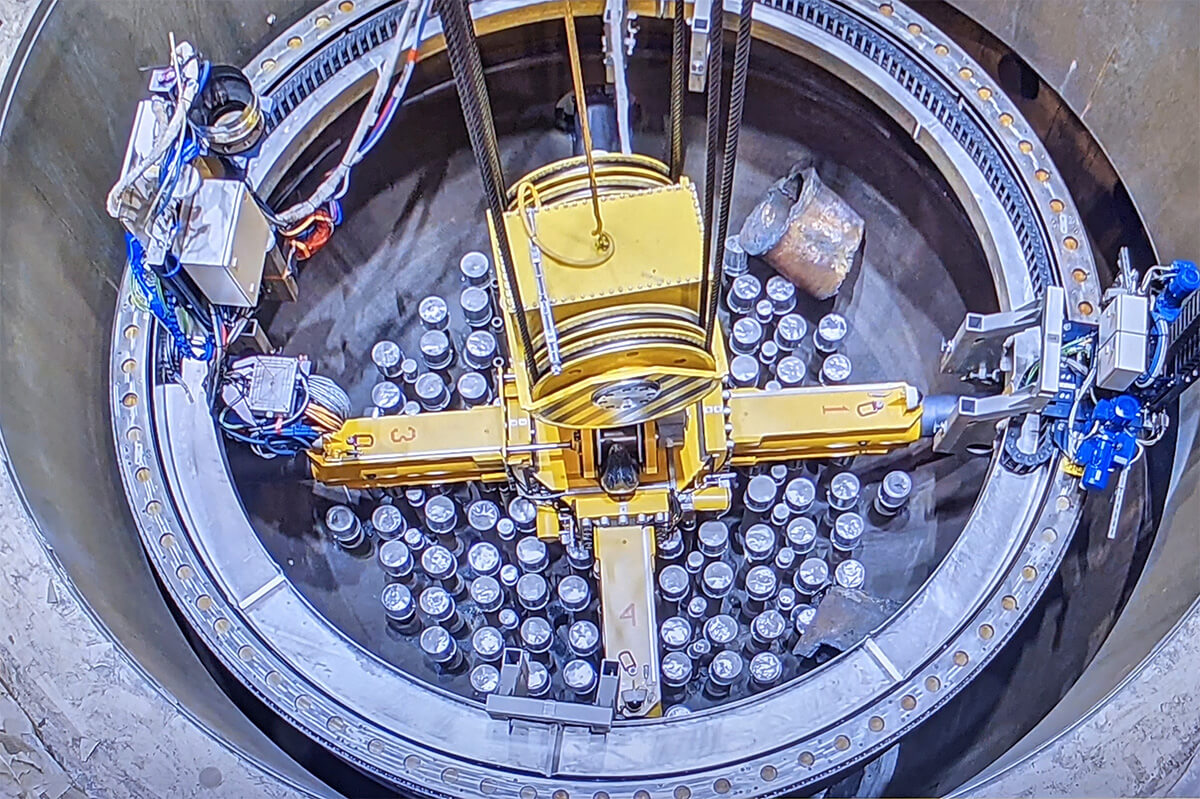

Marking a milestone in nuclear waste management and decommissioning, NUKEM Technologies Engineering Services GmbH (NUKEM), in partnership with Uniper Nuclear Services GmbH (UNS) as part of the UNNU Consortium, has successfully completed the complex dismantling of the fourth and final reactor pressure vessel (RPV) at the Oskarshamn Nuclear Power Plant in Sweden.

This achievement represents the successful conclusion of an ambitious fleet dismantling project. UNS as the consortium lead, managed post-segmentation and the packaging of the cut RPV components into specialized containers, while NUKEM executed the in-situ segmentation of the RPV and the removal of asbestos insulation between the RPV and the biological shield.

This achievement underscores NUKEM's expertise in delivering safe, precise and environmentally responsible nuclear dismantling solutions.

Between July 2020 and December 2024, NUKEM and UNS dismantled four reactor pressure vessels at the Oskarshamn and Barsebäck sites in Sweden. The project's smooth and efficient progression reflects NUKEM’s meticulous planning and extensive dismantling expertise. "By systematically applying lessons learned, we reduced the dismantling time by nearly half from the first to the fourth reactor, demonstrating a remarkable increase in operational efficiency. The project also shows that even the most complex tasks can be carried out successfully, adhering to all safety and radiation protection requirements, and without any incidents,” emphasized Sergey Molodtsov, Managing Director of Operations at NUKEM.

The dismantling of a reactor pressure vessel - one of the largest and most radioactively contaminated components of a nuclear power plant - requires exceptional precision and strict safety compliance. The RPV was successfully cut into transportable segments and prepared for final disposal. The process incorporated state-of-the-art technology, including a specially developed flame-cutting method and innovative tools that enabled safe handling of radioactive materials while ensuring the safety of the project team. Additional challenges, such as the removal of asbestos-containing insulation, were systematically addressed through comprehensive planning and design.

"We take great pride in having competently delivered this highly valuable decommissioning project together with our consortium partner UNS. This achievement highlights NUKEM’s role as an innovator in the field, continuously fostering strong partnerships across the global nuclear industry," remarked Nobuaki Ninomiya, Managing Director of NUKEM and its parent company Muroosystems.

“The success of this highly technical and organisationally challenging project is a testament to the collaborative efforts of all involved stakeholders. We extend our sincere thanks to the license holders BKAB AB, OKG AB and Uniper’s Swedish ND&D program as well as to our consortium partner UNS for their dedication throughout the project”, added Thomas Seipolt, CEO of NUKEM.

The successful completion of this dismantling project strengthens NUKEM's position as a leader in nuclear power plant decommissioning, showcasing the importance of advanced technology and technical expertise in the industry. Serving as a model for future dismantling endeavours, the project exemplifies NUKEM's commitment to excellence in safety and environmental care.

NUKEM Technologies Engineering Services GmbH in Karlstein am Main, Germany, is world-wide active in the areas of management of radioactive waste and spent fuel, decommissioning of nuclear facilities, engineering and consulting. For more than 60 years NUKEM provides high quality products, technologies and services, where Innovation, Solutions and Excellence are closely linked.

Contact:

Yvonne Amend

NUKEM Technologies Engineering Services GmbH

Zeche Gustav 6, 63791 Karlstein am Main

E-mail:

www.nukemtechnologies.de